Copper coil of the motor's upper winding.

2022-10-17

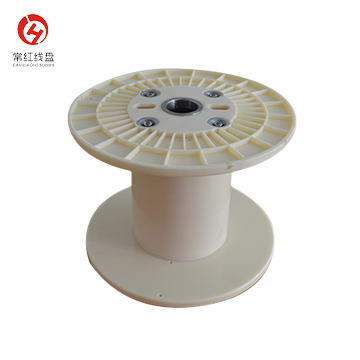

Now let's take a look at high powerCoil diskhow it is wound, and what steps should be taken in the motor coil winding. There are many types of motors, and the winding of each motor coil is also different. Some small motors are as big as eggs, while the core cavity of large motors is straight, with diameters reaching 70 or 80 centimeters, allowing maintenance personnel to work inside the motor core cavity. This size difference leads to different winding steps for the coils. For example, the adjustment of a hand drill rotor can only be done by knowing the wire diameter, number of turns, and pitch, and winding it directly by hand. However, for single-phase, three-phase asynchronous motors or large motors, there are more winding steps.

Depending on the needs of the circuit, choose the winding method. When winding hollow inductance coils, the winding method should be determined based on circuit requirements, inductance size, and coil wire diameter. Inner winding coils are suitable for high-frequency and ultra-high-frequency circuits. When the number of turns is less than 3 to 5 turns, a skeleton cannot be used, which can have better characteristics. The Q value is high, reaching 150-400, and stability is also high. Single-layer tightly wound coils are suitable for shortwave and medium-wave circuits, with a Q value reaching 150-250 and high stability.

Coil disks are customized to ensure the current-carrying capacity and mechanical strength of the coils, selecting the appropriate wire. The coil should not be wound with too thin wire to avoid increasing the coil resistance and reducing the Q value. At the same time, if the wire is too thin, its current-carrying capacity and mechanical strength are very low, making it easy to burn out. Therefore, it is necessary to choose the appropriate winding wire while ensuring the coil's current-carrying capacity and mechanical strength.

WindingCoil disktaps should be clearly marked. Coils with taps should be clearly marked for easy installation and maintenance. First, it is convenient for processing. Multi-strand wires are relatively weak and have good flexibility, while copper wires of the same diameter are harder and more difficult to process. Second, it reduces the skin effect. The working frequency of wireless charging is 100-200kHz, and high-frequency current passes through the conductor, then the distance between the conductor surface and the conductor. As the gap gradually increases, the current density in the conductor decreases exponentially, meaning that the current in the conductor will gather on the surface of the conductor, which is the skin effect. The skin effect of thick single-strand copper wire is significant, leading to heating and reduced efficiency; the single enameled wire in multi-strand wires is insulated from each other, with a small diameter, which helps reduce the skin effect.

Contact Us

Mailbox:

wangyumei630@163.com

Tel:

086-769-85707005

Mobile:

086 132 6843 4928

Address:

Building 3, Wanshan Factory, No. 38 Hulin Road, Humen Town, Dongguan City