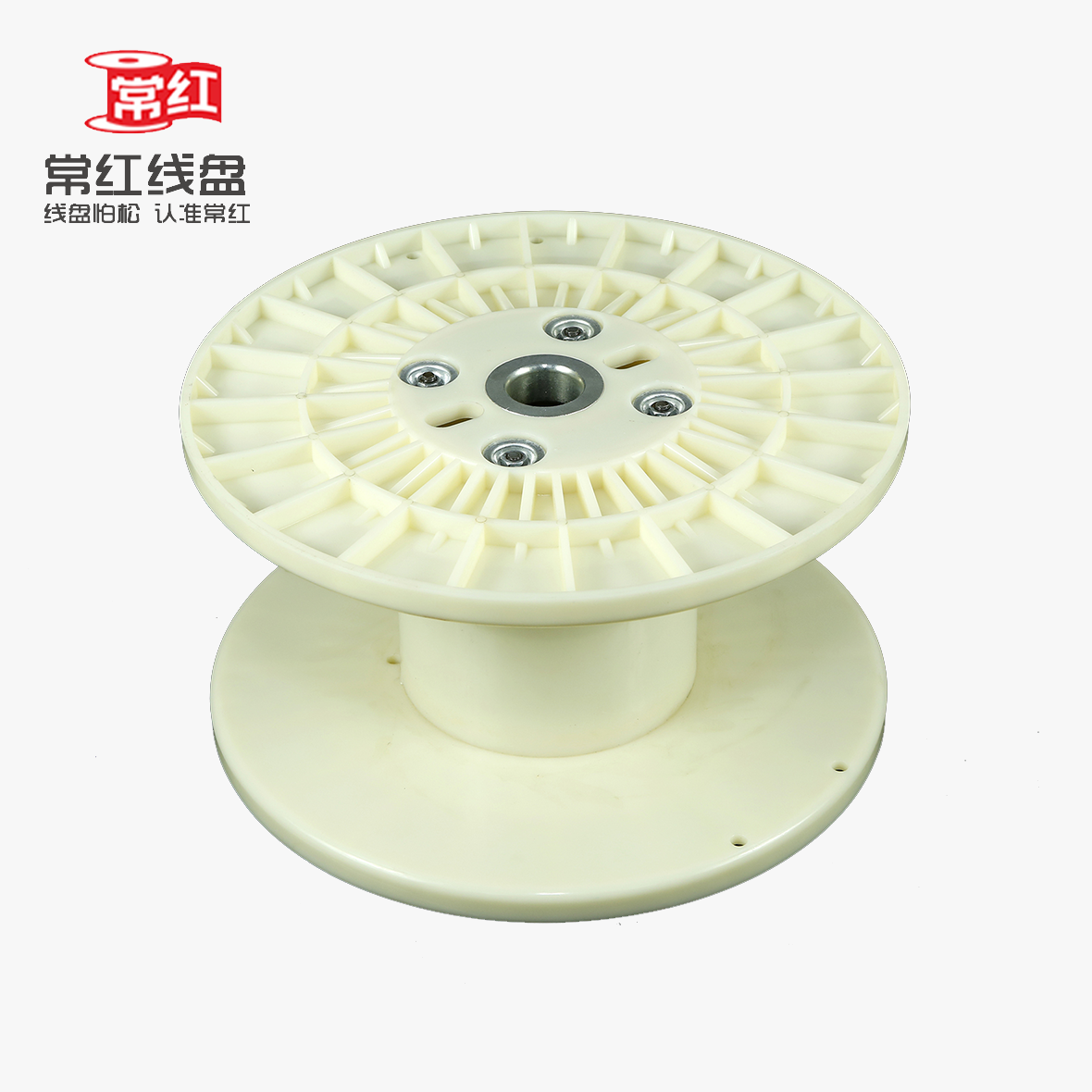

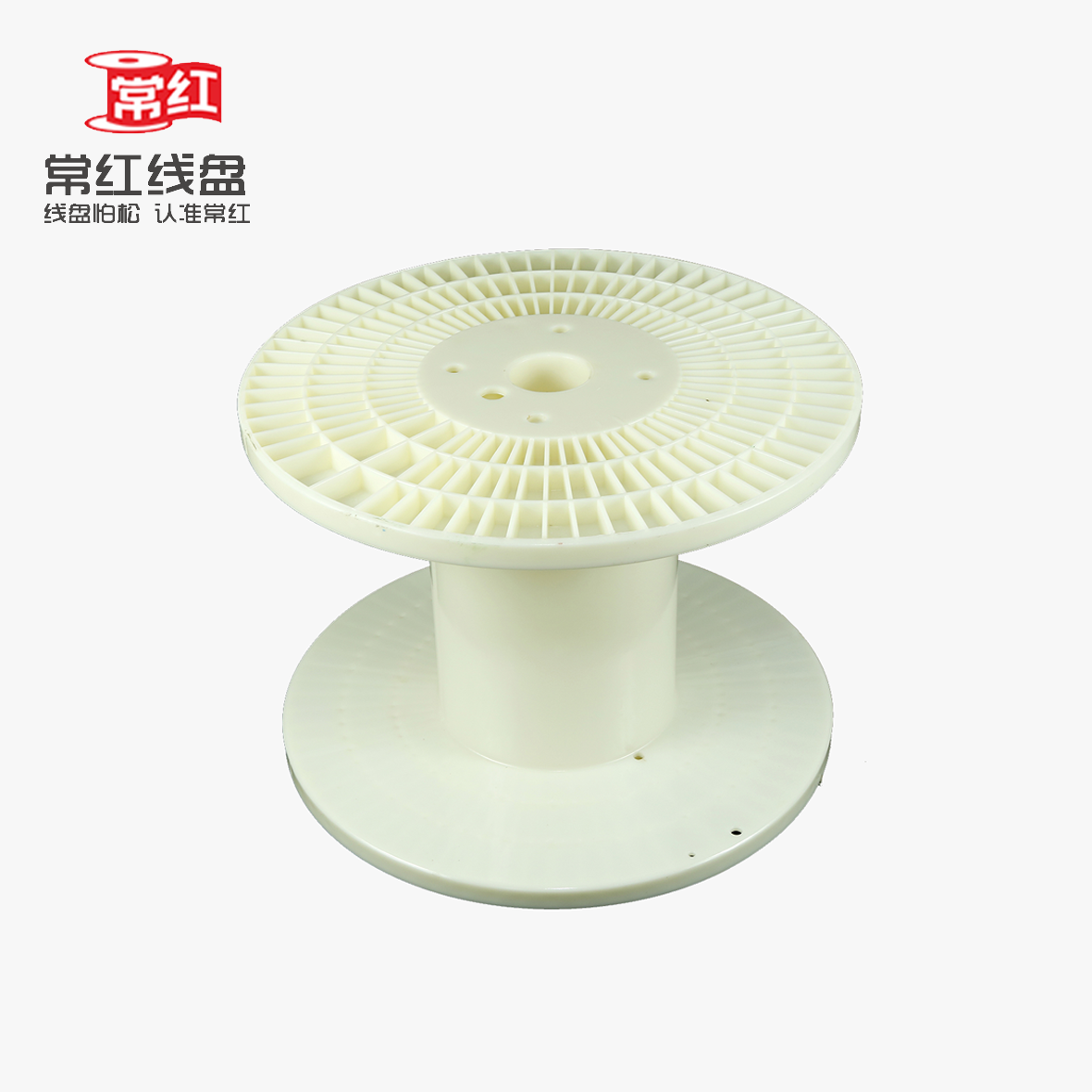

Introduction to the Production of Plastic Spools

Plastic spoolIt is also very common in the industry, and today we will continue to introduce it.

2024-06-14

Plastic spoolIt is also very common in the industry, and today we will continue to introduce it.

Key points for operating the extruder

(1) Before starting, the operator should check the lubrication, transmission, electrical control, and other conditions of each part of the equipment. If any problems are found, they should be resolved immediately by relevant personnel.

(2) Select and match the mold according to product requirements, and adjust the distance between the mold core and the mold sleeve to prevent excessive deviation in the thickness of the plastic layer.

(3) Start the heating system 2 to 3 hours in advance, and adjust the temperature of each section according to the process specifications to prevent temperature control from being too high or too low.

(4) Before production, check the quality of the semi-finished products according to the process specifications, and only start production after confirming they are qualified.

(5) Prepare a suitable winding spool according to the product length, and ensure the wire arrangement is tight and neat.

(6) Prepare and pull the rope, and test the operation of the screw, pulling speed, unwinding and winding rotation, heating control system, various electrical switches, and water flow conditions. Confirm that there are no issues before starting production.

(7) Start the machine

(1) Add qualified plastic to the hopper, open the gate, and start the screw. The operator should pay attention to the feeding situation and observe the voltage and current indicators. At this time, the operator must not leave the post to prevent problems.

(2) After the plastic is extruded from the die, observe the plasticization of the plastic. When the plasticization is about to be good, start adjusting the mold to ensure the plastic thickness is uniform and prevent excessive thickness deviation.

(3) Sample and check the thickness and surface quality according to process specifications, such as: air holes, lumps, plasticization state, etc.

(4) Once everything is normal and meets process requirements, immediately organize personnel to start the machine. During operation, tasks should be divided and closely coordinated.

(5) Thread the lead wire, start pulling, control the speed of the screw and pulling according to the specified thickness, and arrange the cable neatly on the spool with the wire rack after passing through the pull.

(6) During normal production operation, pay attention to the following points:

i. The quality of the product.

ii. The mechanical operation of each part of the equipment.

iii. The control of the heating system.

iv. The speed variation of the screw and pulling.

v. Maintain three diligence: diligent measurement of outer diameter (thickness); diligent quality inspection; diligent observation of equipment.

(7) Keep records such as labels, tracking cards, and record sheets.

(8) Stopping: First, cut off the pulling power supply, then stop the main machine. Timely remove the mold core and mold sleeve, loosen the contact bolts between the head and the body, close the hopper gate, push out the head, and clean out the plastic inside the barrel. Organize personnel to clean the head and mold.

(1) The machine should be stopped in the following situations:

i. After completing the production task, stop in time to clean the head.

ii. If the temperature control is too high, it can cause plastic charring, and the head and screw need to be cleaned.

iii. If stopped for more than one hour, the head needs to be cleaned.

iv. If there are other reasons for stopping, such as power failure, water stoppage, line waiting, lack of spools, equipment or personal accidents, the head needs to be cleaned.

(2) The head and screw must be cleaned thoroughly, and after cleaning, they should be reassembled in a timely manner.

(3) Record the shift handover and prepare for the next shift's production work, such as molds, spools, semi-finished products, etc.

(4) Clean the machine according to job responsibility requirements.

(5) After stopping, check the power supply, water source, and various parts of the equipment. Confirm that there are no issues before turning off the power and water supply and leaving the machine.

Plastic spoolThese are the key points for operating the extruder, and everyone is welcome to come and purchase.

Contact Us

Mailbox:

wangyumei630@163.com

Tel:

086-769-85707005

Mobile:

086 132 6843 4928

Address:

Building 3, Wanshan Factory, No. 38 Hulin Road, Humen Town, Dongguan City