How to conduct visual inspection of coils

2022-10-17

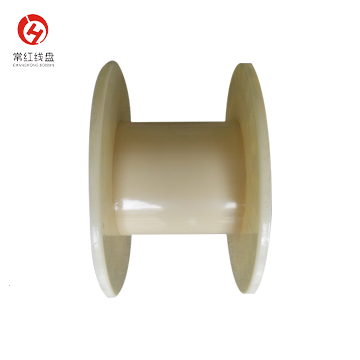

CoilHow to check if it is qualified through appearance inspection? 1 Appearance: The coil winding is uniform, the spacing is uniform, the glue is evenly applied, and the flatness is ≤1.5mm; the coil should be tightly attached to the winding device without loosening, and the enameled wire should not be raised (the adhesion between the coil and the spool should be ≥5N); the frame must not be damaged or dented; the ferrite must not be damaged and must be firmly bonded in the groove with epoxy resin; the connection between the terminal and the copper wire must be sealed with heat shrink tubing, which must not be damaged; the surface of the plastic parts should be smooth, neat, and free of defects such as deformation, discoloration, burrs, and flash.

2 Size: The size meets the requirements of the technical drawings and actual installation requirements; 3 Marking and packaging: Quantitatively packed into boxes, with the product name, model, specifications, quantity, manufacturer name, production batch number or date of manufacture marked on the outside of the box; the coil spool should be marked with the production date (the magnet should also be marked with the production date), and the coil spools should be interconnected with isolation layers.

At the same time, the plastic foam paper should be properly packaged according to the specified quantity and specifications. After packaging, there should be no "loose or poor packaging" and mixed packaging; the winding wire should not have friction or collision, and should be neatly stacked. 3.1 Appearance: The coil should be wound evenly, with uniform spacing, evenly applied glue, and flatness ≤1.5mm; the coil should be tightly attached to the spool without loosening, and the enameled wire should not be raised (the adhesion between the coil and the spool should be ≥5N); the frame must not be damaged or dented; the ferrite must not be damaged.

The coil spool must be firmly bonded to the groove with epoxy resin and fixed; the connection between the terminal and the copper wire must be sealed with heat shrink tubing, which must not be damaged; the surface of the plastic parts should be smooth and neat, without deformation or discoloration, and the spool frame with defects such as burrs and flash must not be damaged or dented. 3.2 Size: The size meets the requirements of the technical drawings and actual installation requirements; 3.3 Marking and packaging: Quantitatively packed into boxes, with the product name, model, specifications, quantity, manufacturer name, production batch number or date of manufacture marked on the outside of the box; the coil spool should be marked with the production date (the magnet should also be marked with the production date).

CoilThere should be isolation layers between the spools. At the same time, appropriate packaging such as plastic foam paper should be used according to the specified quantity and specifications. After packaging, there should be no "loose, poor, or mixed packaging"; the coil wire should not be arbitrarily rubbed or collided, and should be neatly stacked; the packaging should have reliable anti-collision measures. 3.4 Wire diameter, number of turns, inductance, Q value (quality factor), and resistance of the enameled wire: Must meet the technical requirements of various model drawings, and the resistance of the enameled wire at room temperature must not exceed 0.24Ω/m. 3.5 Electrical strength: Electrical strength testing should be conducted using a withstand voltage tester. Withstand voltage (terminal to magnetic core) 1800V/5mA/1min without breakdown or flashover; withstand voltage (terminal to coil surface): 500V/5mA/1min, without breakdown or flashover.

Contact Us

Mailbox:

wangyumei630@163.com

Tel:

086-769-85707005

Mobile:

086 132 6843 4928

Address:

Building 3, Wanshan Factory, No. 38 Hulin Road, Humen Town, Dongguan City