Issues to pay attention to during the transportation of cable reels.

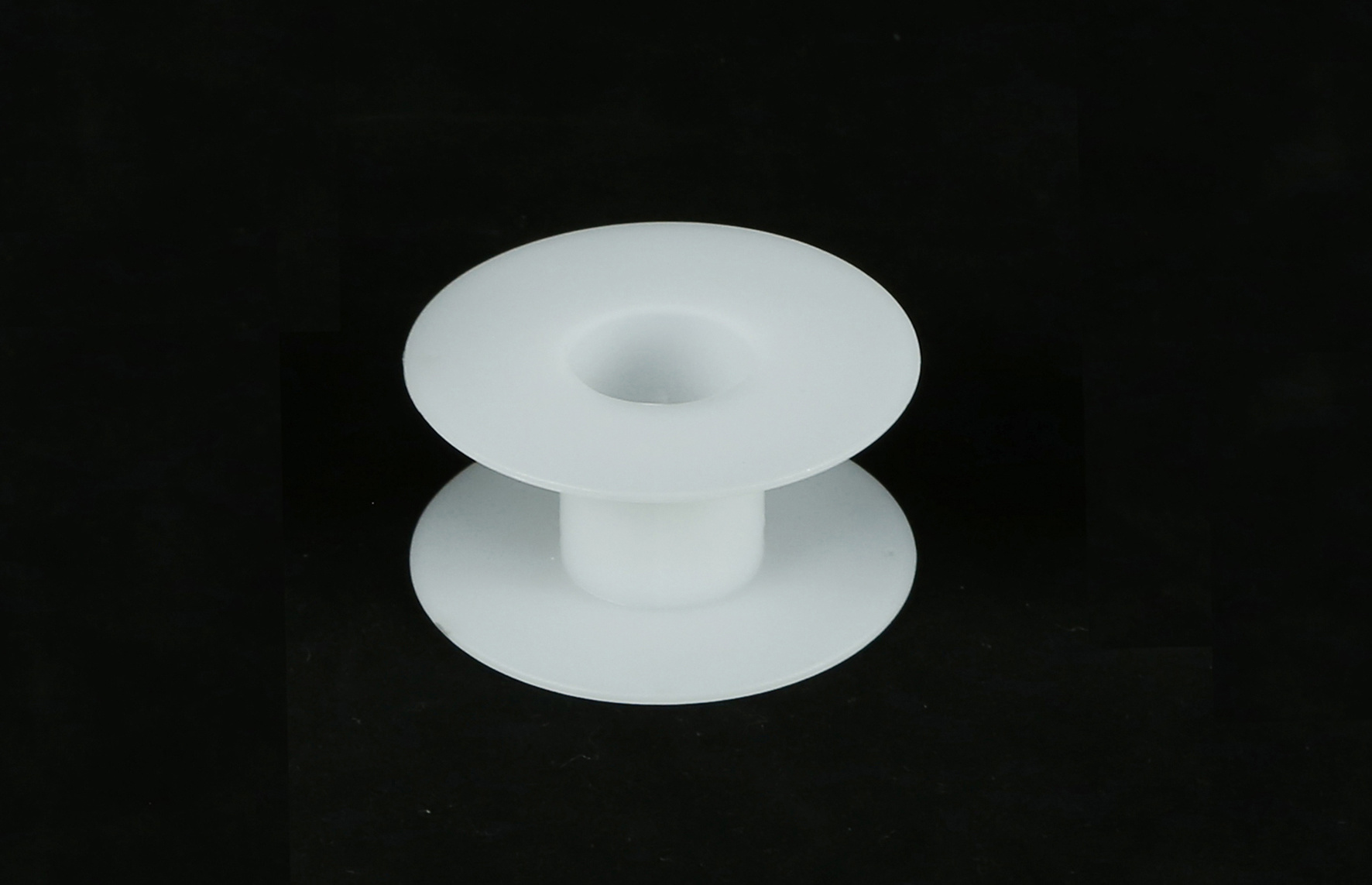

Cable reels are specialized tools for electric wires and cables. Cable reels are mostly made of steel structures and steel-wood structures. The steel structure is sturdy, not easily damaged, provides good protection for cables, and can be reused, which is why it is widely used in practice. Wooden cable reels, due to their short lifespan and poor sturdiness, have basically been eliminated.

2022-02-15

Cable drumIt is a type of reel specifically designed for wires and cables. Cable drums are mostly made of steel structures and steel-wood structures. The steel structure is sturdy, not easily damaged, provides good protection for cables, and can be reused, which is why it is widely used in practice. Wooden cable drums, due to their short lifespan and poor sturdiness, have basically been eliminated.

During transportation, cable products need to go through a certain transportation and storage process from the factory to the user's hands, so the following issues should be noted:

1. Before transportation, check whether the cable packaging is intact, whether the cable certificate is filled out correctly, whether the cable end caps are tight, and whether the cable is securely fixed on the cable drum. Check for any looseness or detachment of the side plates of the cable drum. Only proceed with transportation after confirming there are no issues.

2. When unloading, if there is no lifting equipment, it is strictly forbidden to push the cable drum directly off the transport vehicle. Pushing it off directly not only damages the cable drum but also makes the cable susceptible to mechanical damage. Smaller cable drums can be rolled down a ramp made of wooden boards, using a winch or rope to slowly roll the cable drum down the slope.

3. Cable drums are not allowed to be loaded flat. Laying them flat will cause the cables to unwind and may damage both the cables and the cable drum.

When loading, a forklift or crane should generally be used. It is strictly forbidden to lift multiple cable drums at the same time, as this will cause uneven stress on the drums, making the center of gravity unstable, which can easily lead to slipping and falling.

For cable drums already loaded on the vehicle, they should be well cushioned to prevent shaking, collisions, or tipping. When handling looped power cables, they should not be thrown. During transportation, they should be handled gently to avoid mechanical damage. Looping soft wires can be stacked or transported in containers, but the stacking height should not be too high, and the stacks should be in close contact or have good fixing measures to prevent collapse and damage to the cables.

4. Rolling of cable drums. When rolling on the ground, the movement of cable drums must be controlled within a small distance. The rolling direction must follow the direction indicated on the side of the cable drum. If rolled in the opposite direction, it will cause the cable to unwind and loosen, leading to detachment. After the cable is transported to its destination, it should be checked promptly for any cable damage. If any damage is found, contact the manufacturer immediately for assistance. Do not use damaged cables to prevent adverse consequences.

For important project cables or export cables, protective sealing plates should be nailed inside the cable drum openings. It is best for the protective sealing plates to be tightly fixed against the cable package. In case the cable drum is impacted during transportation, the protective sealing plates can provide better protection.

5. When loading cables, the ends should be reliably sealed, and protective covers (caps) should be added to the cable ends that extend outside the drum. During transportation, ensure there is a certain gap on the side of the cable drum to prevent the cable end caps from being damaged.

6. On vehicles, ships, and other transport tools, cable drums should be arranged in a crisscross manner. The cable drums must be placed securely, and both sides should be firmly fixed to the transport vehicle with steel wire ropes. Additionally, triangular wedges should be used at the bottom of the cable drums to prevent shaking, collisions, or tipping during transportation.

7. When transporting large cable drums, attention should be paid to selecting road transport equipment. If using a heavy-duty truck, ensure that the height of the truck complies with the height restrictions of bridges, tunnels, etc., on the traffic road. If it exceeds the limit, a specialized trailer can be used to lower the transport height.

The above is aboutCable drumthe relevant content sharing on issues to pay attention to during transportation. Only by adhering to the above points can the safe transportation of cable drums be ensured. I hope the above introduction can help everyone!

Contact Us

Mailbox:

wangyumei630@163.com

Tel:

086-769-85707005

Mobile:

086 132 6843 4928

Address:

Building 3, Wanshan Factory, No. 38 Hulin Road, Humen Town, Dongguan City