The Impact of Poor Quality Cable Reels

What are the impacts of low-quality cable reels? Generally, there are some aspects to pay attention to regarding the protectors inside the cable reels. It is advisable to conduct inspections and maintenance after the product has been used for a period of time to ensure that it can correctly detect circuit faults and take appropriate power-off measures to avoid false alarms and power outages. The quality and design of the product fundamentally determine its lifespan, while the correctness of the operation process and the appropriateness of the methods are key influencing factors.

2022-02-13

Inferior qualityCable reelWhat impacts will there be? Generally, there are some precautions regarding the protectors inside the cable reel, such as it is good to conduct inspections and maintenance after the product has been used for a period of time, to ensure it can correctly detect circuit faults and take appropriate power-off measures to avoid false alarms and power outages.

1. Inferior quality cable reels may have non-flame-retardant and non-impact-resistant materials for the reel body and socket panel. Prolonged use can lead to burning, blackening, and in severe cases, fire. They may also become deformed due to accidental bumps, affecting the normal use of the cable reel.

2. If the protector of the cable reel is not strong, or if there is simply no protector, the cable will operate under overheating and overload conditions for a long time. This will cause the cable to remain at excessively high temperatures, which will also reduce insulation performance and, in severe cases, lead to fire.

3. If the cable reel operates in an environment with corrosive substances for a long time, even high-quality products may encounter problems. The protective layer of the cable may be chemically eroded or corroded over time, leading to failure of the protective layer and reduced insulation performance. There are also some precautions regarding the protectors inside the cable reel; it is necessary to check whether the cable reel and cable have multiple damages or are about to be damaged due to prolonged use. This requires regular comprehensive inspections of the cable reel to resolve issues and eliminate potential hazards.

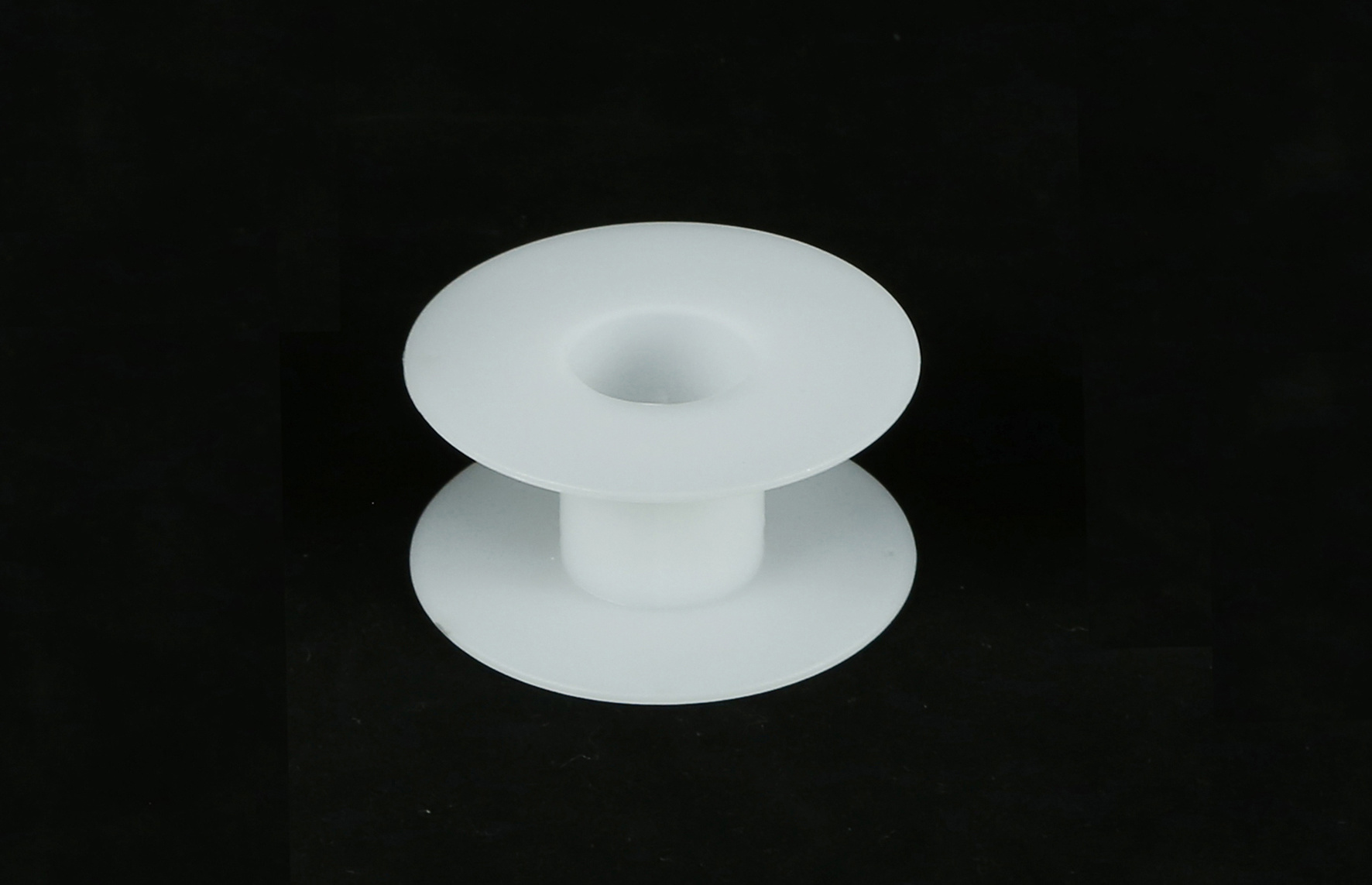

A wire reel or cable drum refers to a spool that can wind wires and cables. The wire reel or cable drum is equipped with national standard sockets or industrial sockets, leakage protectors, and power indicator lights, used as outdoor power sources. To facilitate movement and carrying, small cable reels should have a spool support and handle, while larger cable reels with more winding cables are equipped with wheels. When conducting high-voltage tests on the cable drum, staff must maintain high concentration to avoid unnecessary safety issues.

Even if the working conditions at the test site are poor, staff should not lower safety requirements. At that time, the staff present should be divided into roles, and safety precautions should be detailed. The safety of each staff member must be guaranteed. During the test, it should be fully enclosed, with warning signs to alert passersby not to approach, and staff should be dispatched for supervision to prevent accidents. Fencing should also be set up around the test site. Staff should also be dispatched to guard the other end of the cable drum.

The above is about inferior qualityCable reeland its related impacts, hoping to help everyone!

Contact Us

Mailbox:

wangyumei630@163.com

Tel:

086-769-85707005

Mobile:

086 132 6843 4928

Address:

Building 3, Wanshan Factory, No. 38 Hulin Road, Humen Town, Dongguan City